budada birta kaarboonyl

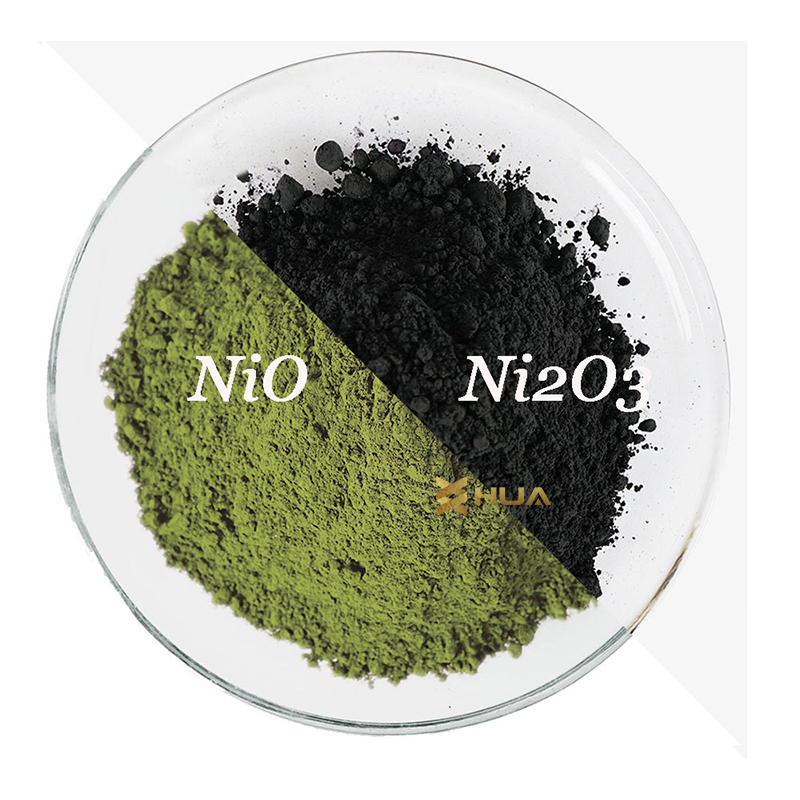

Sharaxaada Alaabta

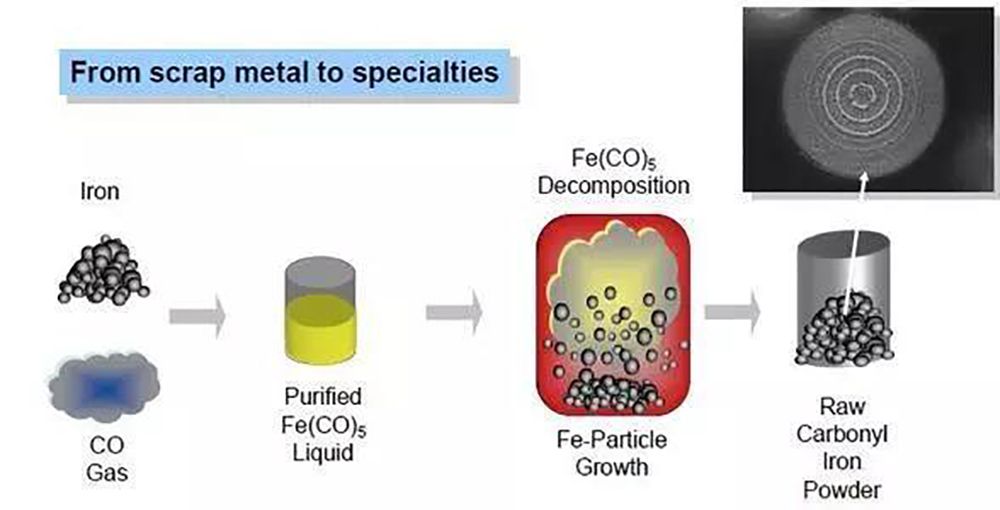

Budada birta ee Carbonyl waa nooc ka mid ah budada birta ah ee aadka u fiican, kaas oo leh sifooyinka nadiifnimada sare, dareeraha wanaagsan, kala firdhinta wanaagsan, dhaqdhaqaaqa sare, sifooyinka korantada ee aad u fiican, cadaadis wanaagsan iyo qaabaynta qaabaynta.Budada birta ee Carbonyl waxaa si weyn loogu isticmaalaa militariga, elektiroonigga, kiimikaadka, daawada, cuntada, beeraha iyo beeraha kale.Budada birta ee Carbonyl waxaa loo diyaarin karaa qaabab kala duwan sida fiber, flake ama kubbad iyadoo loo eegayo shuruudaha si loo daboolo baahiyaha kala duwan ee macaamiisha.

Tilmaamid

| Shayga | Halabuurka Kiimikada | Hanti Jireed | |||||||

| Fe | C | N | O | APP.Cufnaanta | Taabo Cufnaanta | Cabbirka Walxaha Laser-ka | |||

| ≥% | ≤% | ≥ | ≥ | D10 | D50 | D90 | |||

| HR1-1 | 98 | 0.8 | 0.6 | 0.4 | 2.2 | 4 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR1-2 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.9 | 0.6-1.5 | 2.0-3.0 | 4.5-8.0 |

| HR1-3 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.8 | 1.0-3.0 | 3.0-5.0 | 5.0-12.0 |

| HR1-4 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 1.5-3.5 | 5.0-6.0 | 11.5-16.5 |

| HR1-5 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.0-4.0 | ≥6.0 | 44915 |

| HR1-6 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 4 | 1.5-2.5 | 3.0-4.0 | 5.5-8.5 |

| HR1-7 | 98 | 0.8 | 0.7 | 0.4 | 2.5 | 4 | 2.0-3.6 | 4.0-5.0 | 7.0-11.0 |

| HR1-8 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.6-4.0 | 5.0-6.0 | 11.5-14.5 |

| HR2-1 | 99.5 | 0.05 | 0.01 | 0.3 | 2.5 | 3.8 | 0.58-1.5 | ≤3.0 | 4.5-8.0 |

| HR2-2 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 0.9-3.0 | 3.0-5.0 | 5.5-12.0 |

| HR2-3 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 1.5-3.0 | 5.0-8.0 | 10.0-18.0 |

| HR2-4 | 99.5 | 0.1 | 0.05 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-5 | 99.5 | 0.4 | 0.2 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-6 | 99.5 | 0.05 | 0.01 | 0.4 | 2.5 | 3.8 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR2-7 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 1.5-3.0 | 3.0-5.0 | 5.5-11 |

| HR2-8 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 2.0-3.5 | 5.0-8.0 | 10.0-15.0 |

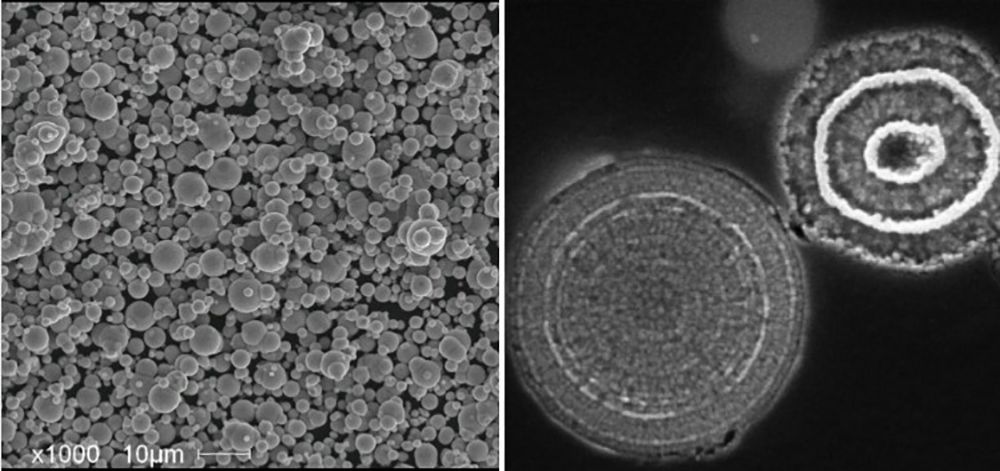

Sem

Faa'iidada

1.Nadiif sare oo kiimiko ah

2.Alaabada korantada ee aad u fiican

3.Spherical

qayb ,qaab dhismeedka maqaarka basasha

4.0.1-10 micron qayb hoose

5.High socodka, kala firdhisanaanta iyo joogtaynta

6.Hgh dhaqdhaqaaqa ,compressibility iyo guryaha sintering aad u fiican